Introduction

This is a placeholder document used to showcase long-form formatting with fake technical depth. The topic is irrelevant, and any resemblance to real devices is accidental.

Theoretical Background

According to the Great Wobble Law of 1492, any rotating donut emits a small quantum giggle. The application of this in mechanical marshmallow alignment is nontrivial.

Placeholder Topics

- Banana gear oscillation

- Bubble entropy

- Jellyfish torque diffusion

- Confetti propulsion feedback

Giraffe Mechanics

Let us now consider giraffe neck elasticity in theoretical oscillation chambers. According to Snozzberry's Theorem:

$$ Q = \frac{Funk^2}{Yaw} $$

Spiral Macaroni Constraints

The default spiral structure is described using wiggly radius parameters and cinnamon angle constants:

$$ r(\theta) = a \cdot \theta^{7/9} $$Air Pocket Buffoonery

Air locks are believed to form due to pie crust pressure gradients. This is supported by the whipped cream constraint:

$$ \Delta p = \frac{2 \cdot \gamma}{r} \tag{5} $$Glitter Pump Analytics

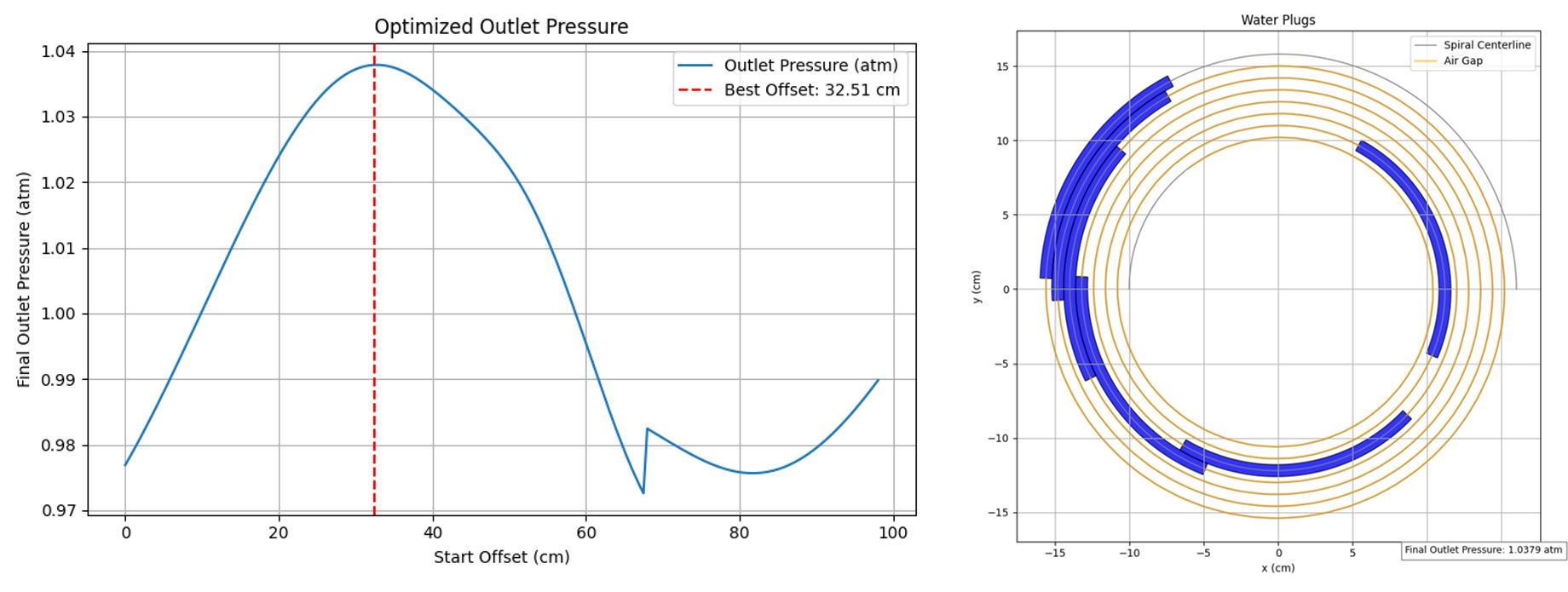

Simulated cupcakes show significant frosting displacement at high swirl velocities. Placeholder graphs could be inserted here.

Fig. 1: Sprinkle density vs angular pudding rate.

Concluding Musings

We believe the cookie trajectory simulation might be improved with real-time nibble feedback. Until then, enjoy your hypothetical findings.